Your requirements - our expertise

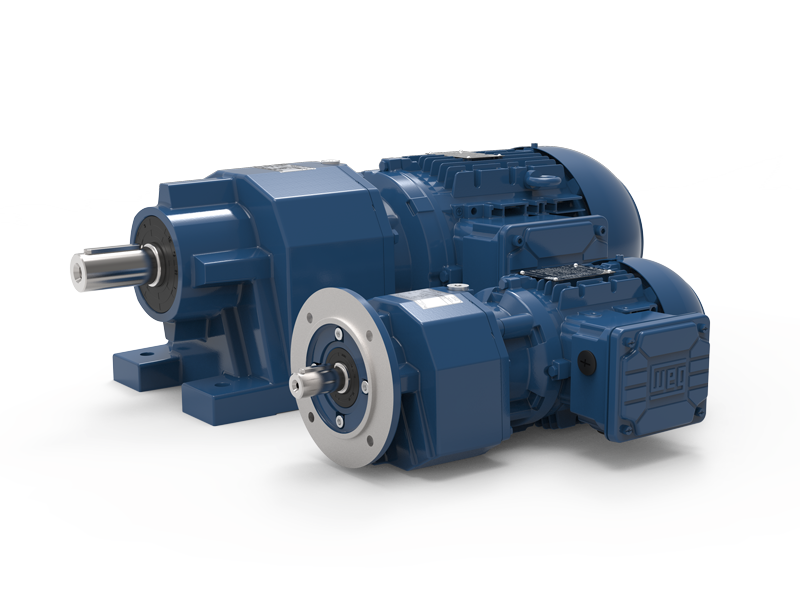

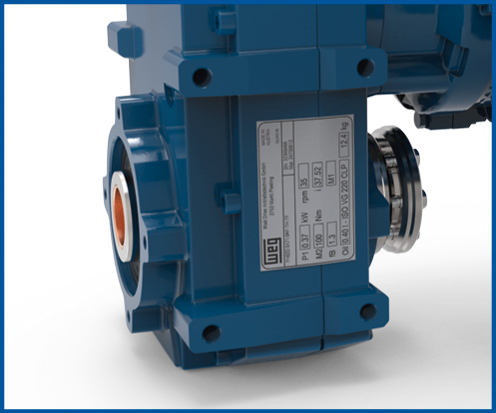

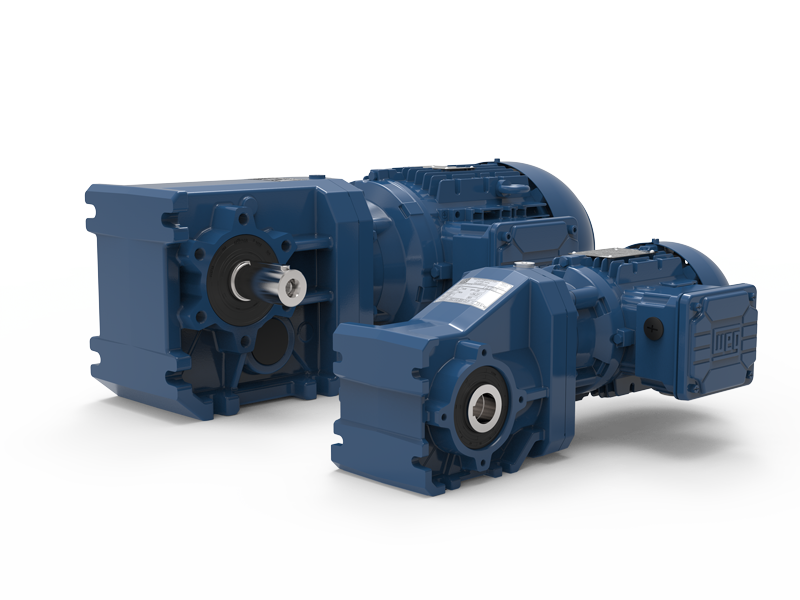

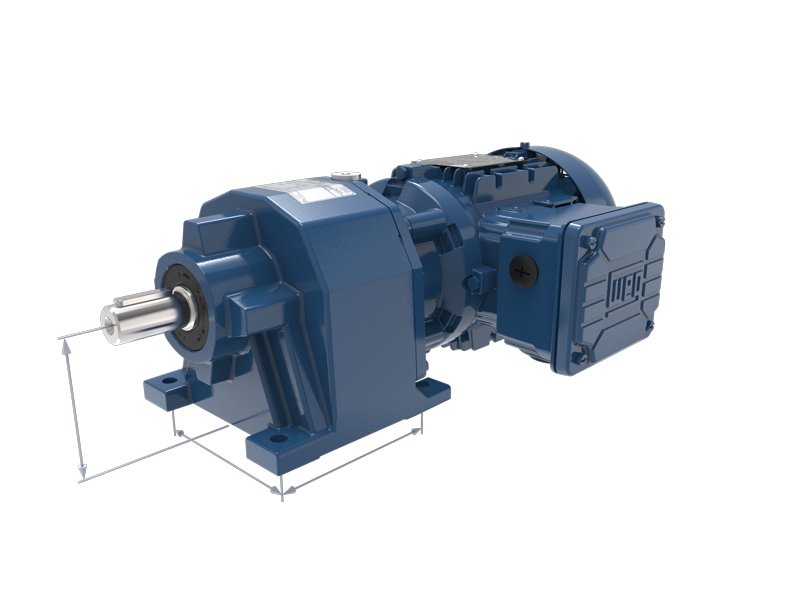

WG20 is the first geared motor range to be completely developed in-house at WEG.

It comprises helical, parallel shaft and helical bevel gear units with torques between 50 and 18,000 Nm. These two-stage units excel with their large ratio range, as well as being exceptionally efficient thanks to the sophisticated design. The light, yet robust, aluminium housing of the gear units in the WG20 range provide a highly versatile and reliable product, with a wide range of possible applications.

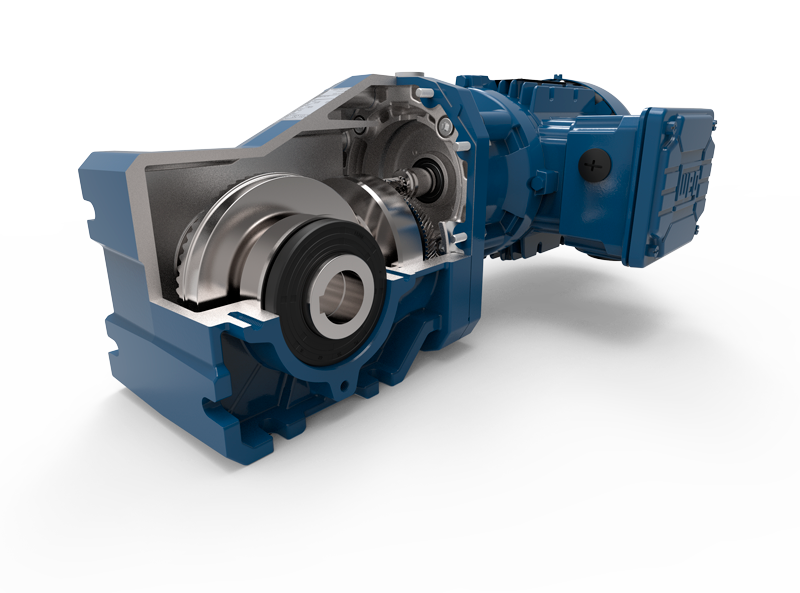

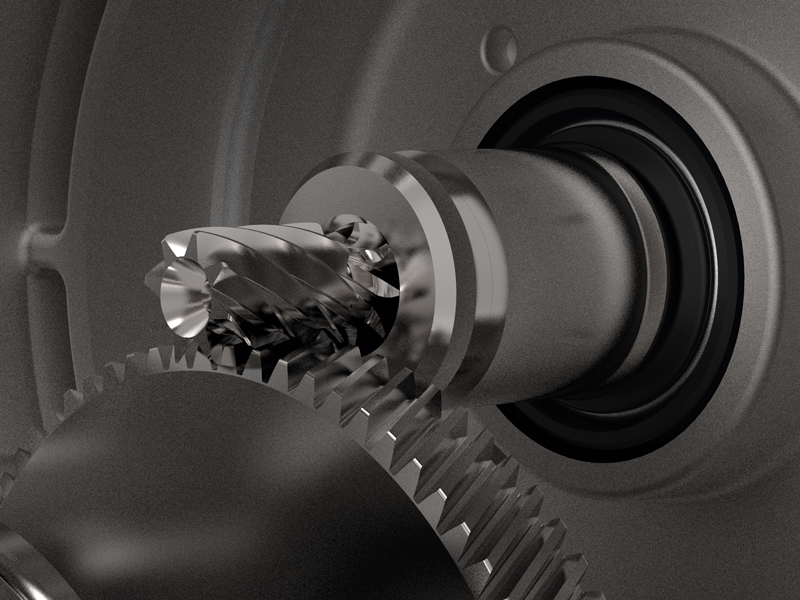

Highly efficient

The gear units are two-stage designs featuring a large ratio range, which in turn makes them highly efficient. Furthermore, the products of the WG20 series demonstrate only extremely low power losses. On the one hand, this is achieved by low circumferential speeds in the input stage and, on the other hand, by reducing splashing losses due to optimised amounts of lubricant. These characteristics also have a positive effect on the gear lifetime. Under normal conditions of use, the geared motors up to 600 Nm are maintenance-free and lubricated for life.

In line with market requirements

For maximum user convenience, the housing of the new gearbox series has been designed in keeping with market requirements. The crucial mounting dimensions of the design correspond with the specifications already established on the market which allows for direct exchange. This means that WG20 geared motors are not only suitable for use in new applications, but can also be easily integrated into existing systems as a replacement or for optimisation purposes.

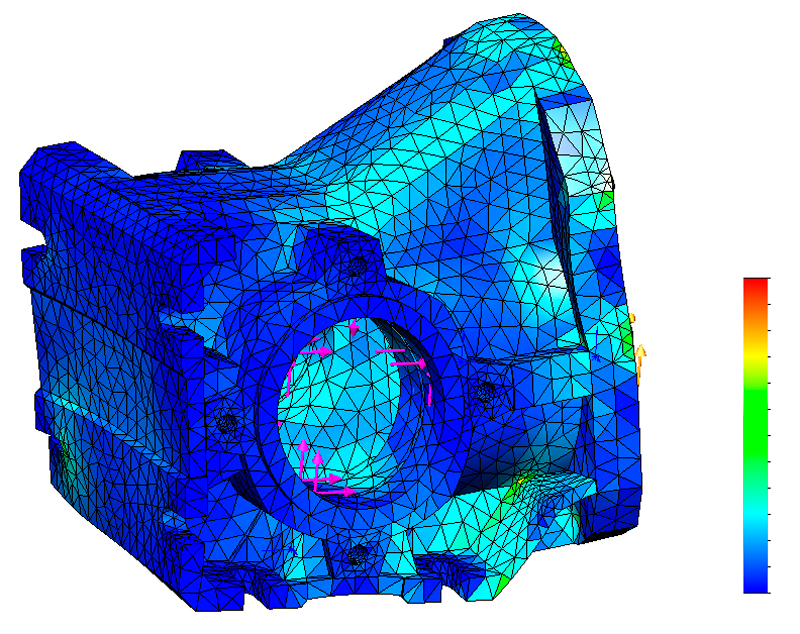

Optimised design

When designing the new gear unit range, the designers paid particular attention to develop a robust housing, opting for a light aluminium construction for the frame sizes up to 600 Nm. The die casting process used in production not only benefits from a smooth surface for demanding hygienic applications, but also features excellent heat conductivity. The housing design additionally enhances this property. The intelligently designed surface encourages heat dissipation from the internal gear parts, thereby aiding more efficient operation and a longer life.

Less noise

The WG20 series gear units are characterised by their smooth, quiet operation. High quality components, which originate almost exclusively from in-house production, engage perfectly to provide the basis for guaranteed low noise operation. Even the flexible gear wheel construction helps reduce noise emission. The small motor pinion allows for lower circumferential speeds in the first stage and reduced noise emissions.

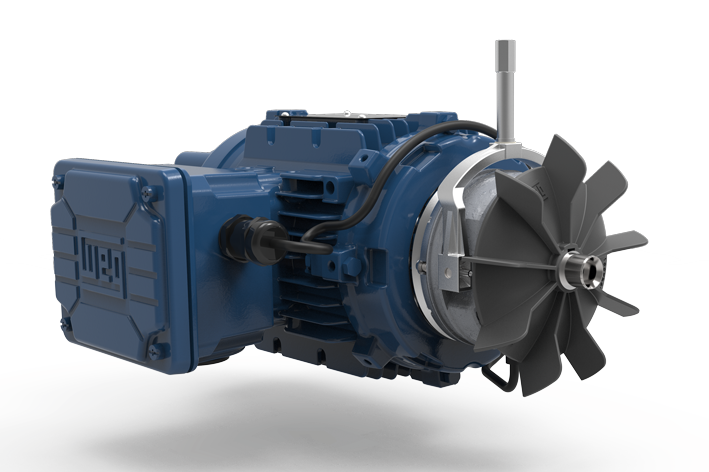

Modular

The particular advantage of the modular motor range is the facility to add system kits to the standard model, allowing a multitude of useful modules to be adapted to the customer’s requirements. Available motor modules include single and double brake systems, ventilation systems, extended terminal box systems, encoder systems (inside and outside the fan cover), back stops, protection caps, and hand wheel.

Advantages for you

A geared motor for the whole world

- Standard mounting dimensions

- Can be switched to different voltages around the world

- Certifications for international markets

Sophisticated design for more efficiency

- Wide speed range

- High efficiency

- Low noise levels

- Optimised oil fill quantity

- Maintenance-free and lubricated for life up to 600 Nm

- High quality components and equipment

- Motors to efficiency class IE4

Comprehensive equipment for more flexibility

- Can be extended by different motor modules

- Temperature monitoring without added costs

- Protection rating IP55 for the standard design

- Switchover to 100/120 Hz characteristic in frequency inverter operation

The optimal programme for lower costs

- Reduction in operating costs for plant operators

- Standard mounting dimensions enable easy interchangeability without system conversion

- Low maintenance costs

- Flexibility and savings for purchasing, technology and warehousing

One company for more service

- Complete drive applications from WEG

- Global WEG branches and sales partners

- Short delivery times

- Innovative product configuration tool

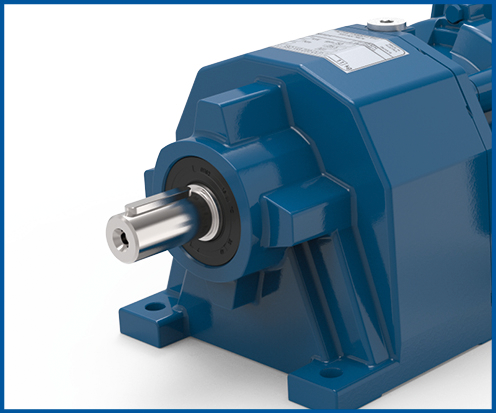

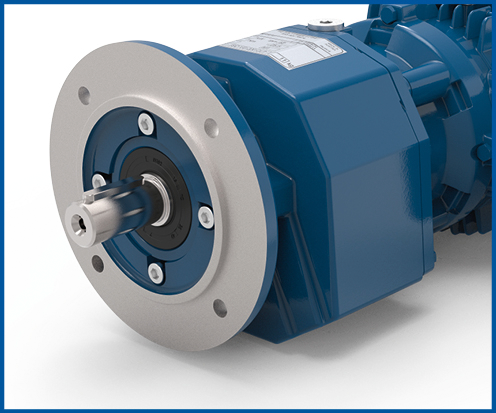

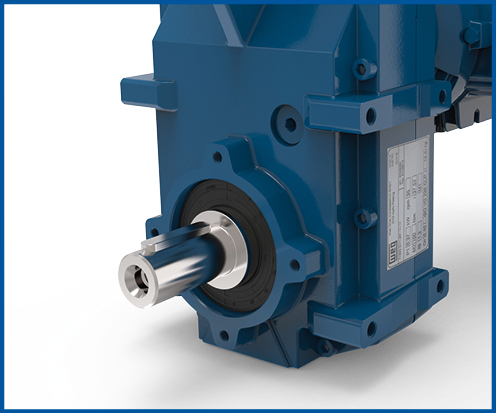

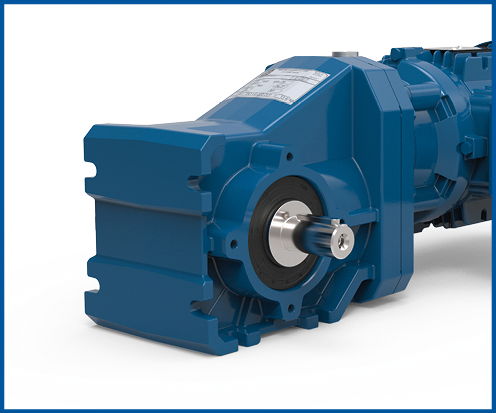

Helical geared motors C

The helical gear units come in 12 housing sizes for nominal torques from 50 to 18,000 Nm and are available in both foot and flange designs. While the two smaller gear units (C00 and C01) are able to perform to their full potential with just two stages, the larger C03 to C16 are available in both two and three-stage versions, for those applications in higher torque ranges.

C00 |

C01 |

C03 |

C05 |

C06 |

C07 |

C08 |

C09 |

C10 |

C13 |

C14 |

C16 |

||

Nominal torque |

[Nm] |

50 |

85 |

200 |

400 |

600 |

820 |

1550 |

3000 |

4500 |

8000 |

13000 |

18000 |

Number of stages |

|

2-stage |

2-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

Ratio range |

2,44 - 47,44 |

3,09 - 66,5 |

3,34 - 286,32 |

3,83 - 328,43 |

3,73 - 375,71 |

5,30 - 351,33 |

5,12 - 368,94 |

4,22 - 306,73 |

4,19 - 246,43 |

4,00 - 204,88 |

5,17 – 206,88 |

5,96 – 234,67 |

|

Speed range at 1400 rpm 50Hz |

[rpm] |

29 - 573 |

21 - 453 |

4 - 419 |

4 - 365 |

3 - 375 |

4 - 264 |

4 - 274 |

5 - 332 |

6 - 334 |

7 – 375 |

7 – 290 |

6 – 252 |

Power range 50Hz |

[kW] |

0,12 - 0,75 |

0,12 - 1,5 |

0,12 - 3 |

0,12 - 7,5 |

0,12 - 7,5 |

0,12 - 15 |

0,18 - 22 |

0,55 - 30 |

1,1 - 30 |

4 - 55 |

4 - 55 |

11 – 75 |

Output shaft |

[mm] |

20 x 40 |

20 x 40 |

25 x 50 |

30 x 60 |

35 x 70 |

40 x 80 |

50 x 100 |

60 x 120 |

70 x 140 |

90 x 170 |

110 x 210 |

120 x 210 |

Output flange IEC |

[mm] |

120/140/160 |

120/140/160 |

140/160/200 |

160/200/250 |

200/250 |

250/300 |

300/350 |

350/450 |

350/450 |

450/550 |

450/550 |

550/660 |

Housing material |

Aluminium |

Cast iron |

|||||||||||

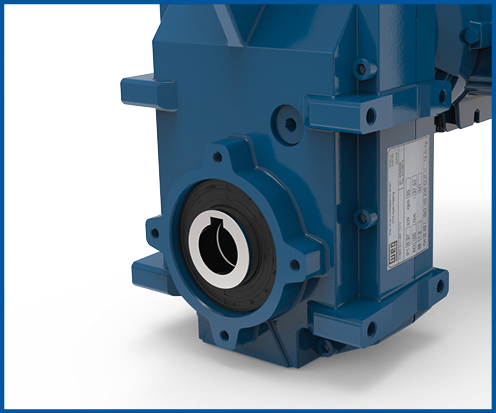

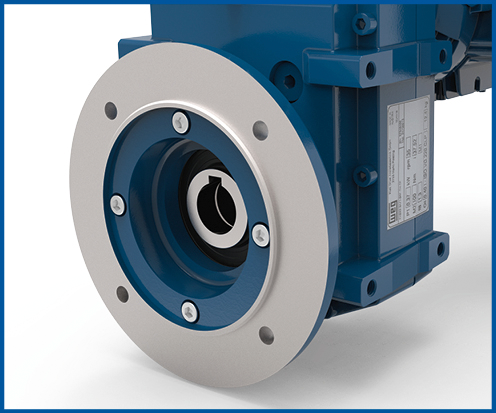

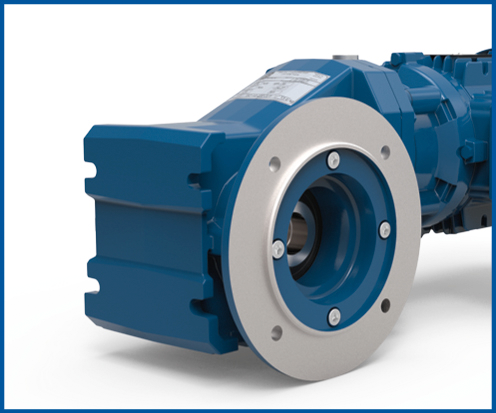

Parallel shaft geared motors F

Thanks to their structural design, parallel shaft gear units are particularly suitable for conveyor technology applications. All 11 sizes can be fitted with either a hollow shaft, output shaft, mounting flange or shrink disc. The ratio range of gear unit sizes F04 to F15 can be extended by a third gear stage.

|

|

F02 |

F03 |

F04 |

F05 |

F06 |

F07 |

F08 |

F09 |

F10 |

F12 |

F15 |

Nominal torque |

[Nm] |

130 |

220 |

400 |

600 |

820 |

1550 |

3000 |

4500 |

8000 |

13000 |

18000 |

Number of stages |

|

2-stage |

2-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

2-/3-stage |

Ratio range |

|

3,93 - 97,85 |

3,85 - 70,17 |

4,42 - 422,98 |

5,17 - 487,67 |

4,41 - 412,64 |

4,29 - 305,42 |

4,09 - 358,52 |

4,16 - 288,50 |

4,38 – 246,57 |

4,64 – 220,67 |

5,84 – 259,81 |

Speed range at 1400 rpm 50Hz |

[rpm] |

14 - 356 |

20 - 363 |

3 - 316 |

3 - 271 |

3 - 317 |

5 - 327 |

4 - 343 |

5 - 337 |

6 – 342 |

7 – 323 |

6 – 257 |

Power range 50Hz |

[kW] |

0,12 - 1,5 |

0,12 - 3 |

0,12 - 3 |

0,12 - 5,5 |

0,12 - 15 |

0,12 - 15 |

0,55 - 22 |

0,55 - 30 |

4 - 55 |

4 - 55 |

11 – 75 |

Output shaft/Ø hollow shaft |

[mm] |

25 x 50 / 25 |

25 x 50 / 30 |

30 x 60 / 35 |

35 x 70 / 40 |

40 x 80 / 40 |

50 x 100 / 50 |

60 x 120 / 60 |

70 x 140 / 70 |

90 x 170 / 90 |

110 x 210 / 100 |

120 x 210 / 120 |

Output flange IEC |

[mm] |

160 |

160 |

200 |

250 |

250 |

300 |

350 |

450 |

450 |

550 |

660 |

Housing material |

Aluminium |

Cast iron |

||||||||||

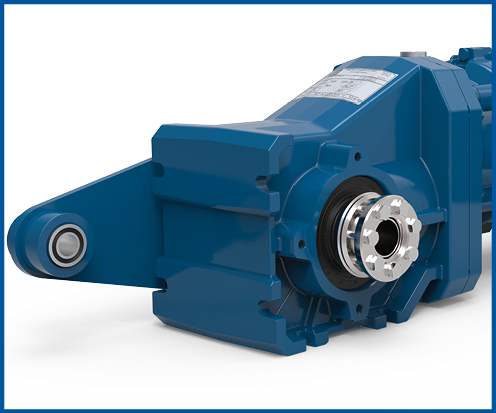

Helical bevel geared motors K

Helical bevel gear units are suitable for a multitude of applications. The two-stage basic design is extended by a third gear stage upward of 200 Nm. K gear units can also be equipped with a hollow shaft, output shaft, shrink disc, torque arm and mounting flange.

|

|

K02 |

K03 |

K04 |

K05 |

K06 |

K07 |

K08 |

K09 |

K10 |

K12 |

K15 |

Nominal torque |

[Nm] |

110 |

200 |

400 |

600 |

820 |

1550 |

3000 |

4500 |

8000 |

13000 |

18000 |

Number of stages |

|

2-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

3-stage |

Ratio range |

|

3,82 - 68,88 |

4,17 - 217,88 |

5,05 - 277,79 |

4,27 - 245,7 |

4.94 - 198 |

7.91 - 256.14 |

7,45 - 206,12 |

6,94 - 169,25 |

6,64 – 140,95 |

6,60 – 151,11 |

8,61 – 146,69 |

Speed range at 1400 rpm 50Hz |

[rpm] |

20 - 366 |

6 - 335 |

5 - 277 |

5 - 327 |

7 - 283 |

6 - 177 |

7 - 188 |

8 - 202 |

11 – 226 |

10 – 227 |

10 – 174 |

Power range 50Hz |

[kW] |

0,12 - 1,5 |

0,12 - 3 |

0,12 - 4 |

0,12 - 5,5 |

0.18 - 7.5 |

0.25 - 15 |

0,55 - 22 |

1,1 - 30 |

4 - 55 |

4 - 55 |

11 – 75 |

Output shaft/Ø hollow shaft |

[mm] |

25 x 50 / 25 |

25 x 50 / 30 |

30 x 60 / 35 |

35 x 70 / 40 |

40 x 80 / 40 |

50 x 100 / 50 |

60 x 120 / 60 |

70 x 140 / 70 |

90 x 170 / 90 |

110 x 210 / 100 |

120 x 210 / 120 |

Output flange IEC |

[mm] |

160 |

160 |

200 |

250 |

250 |

300 |

350 |

450 |

450 |

550 |

660 |

Housing material |

Aluminium |

Cast iron |

||||||||||

More information about WG20

Get the product brochure with detailed information on our new geared motor range.