Drives for construction machinery: reliable raw material feed in mobile concrete mixing plants

Mobile EUROMIX concrete mixing plants from SBM Mineral Processing (SBM), a member of the international MFL Group, which is headquartered in Oberweis (Austria), enable economical concrete production and processing directly on site. SBM consistently relies on drive systems from Watt Drive (part of the WEG Group) to drive a variety of conveyor belts in its mobile mixing plants. This includes the extremely mobile EUROMIX 400C plant.

SBM specialises in the development and production of concrete mixing plants and in processing and conveying systems for the natural stone and recycling industries. The Austrian company is a full-service supplier in the ready-mixed and prefab concrete sector and has both mobile and stationary concrete mixing plants in its product line. The supermobile EUROMIX 400C unit is one of the company’s special solutions and boasts its own electrical generator for fully autonomous operation. It is compact, powerful and has approval to be transported via the public highway.

The Dutch recycling company Van Gansewinkel uses the EUROMIX 400C to process materials such as excavated soil, bottom ash, sludge and sieved sand into concrete suitable for long-term storage. The plant operates in continuous operation with an effective production capacity of more than 400 t/h. For the 400C model as for other EUROMIX plants, SBM relies on geared motors from Watt Drive for the conveyor belt drives.

Hard work in construction

Several conveyor belts with reliable drive systems are necessary for smooth operation of the concrete mixing plant. The aggregate is weighed and dispensed according to the desired concrete grade and fed to the steep-angle conveyor belt, which in turn transports the material to the double-shaft mixer. Cement, water and the necessary additives are fed directly into the mixer. The resulting concrete can be taken away by lorry or by ready-mix concrete trucks.

Extreme operating and environmental conditions, high availability and optimal plant use impose high demands on the drive systems. The geared motors must be protected against humidity as well as extreme dust loading. Along with robustness, reliability is especially crucial for job-site operation. Particularly for motorway or tunnel construction, a continuous supply of concrete is essential. The compact design and high mobility of the EUROMIX 400C also requires low-profile gear units with flexible mounting options.

Compact powerhouses

The drive technology from Watt Drive used in the EUROMIX mixing plants includes various types of gear units from the K Series with torque ratings from 2,700 to 20,000 Nm. The EUROMIX 400C has a pair of helical bevel geared motors (type KUA 85A 70 134M4) rated at 7.5 kW for the two dispensing belts and an angle parallel shaft geared motor (type CSA 80A 70 161M4) rated at 11 kW for the steep-angle conveyor belt.Helical bevel geared motors: efficiency class IE2, speed 22 rpm at 50 Hz, torque 3,274 Nm, controlled by frequency inverters and housing in UNIBLOCK design. Included motor options: humidity protection, condensation bores, temperature control (PTC), forced ventilation and protective covers

- Helical bevel geared motors: efficiency class IE2, speed 22 rpm at 50 Hz, torque 3,274 Nm, controlled by frequency inverters and housing in UNIBLOCK design. Included motor options: humidity protection, condensation bores, temperature control (PTC), forced ventilation and protective covers

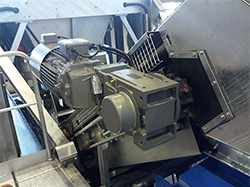

Figure 1: A Watt Drive helical bevel geared motor drives a dispensing belt of the EUROMIX 400C

- Angle parallel shaft geared motors: efficiency class IE2, speed 80 rpm at 50 Hz, torque 1,321 Nm, controlled by frequency inverters and housing in UNIBLOCK design. Included motor options: humidity protection, condensation bores, temperature control (PTC), forced ventilation, protection covers and modular backstop

Figure 2: A Watt Drive angle parallel shaft geared motor drives the steep-angle conveyor belt of the EUROMIX 400C

Versatile, compact and reliable

The reliability and high quality of the geared motors from Watt Drive reinforce the confidence of SBM's customers in the availability and productivity of the EUROMIX concrete mixing plants. Low maintenance, robustness and long life are especially crucial attributes of drives for mobile use in job-site conveyor systems. The combination of high operational reliability and outstanding versatility makes the modular drives units from Watt Drive an optimal solution for flexible, demanding applications such as the EUROMIX 400C. There’s a good reason why SBM relies on gear systems from Watt Drive for all EUROMIX plants.

Info box: Current EUROMIX references

A current project employing the combination of SBM concrete mixing plants and Watt Drive technology is the 4.4-km Götschka Tunnel on the S10 motorway in Austria, which forms the traffic corridor between Linz and Prague. Here three mobile EUROMIX plants (types 2000, 3000 and 4000) will produce a total output of 300,000 m3 of concrete from spring 2012 to 2015. The plants operate 24/7 regardless of season and weather, and thanks to its high-quality configuration – including K-Series gear units from Watt Drive – they fulfil the demanding Austrian specifications for tunnel construction. Watt Drive and SBM are also partners in the on-going construction of the S10 motorway in Austria, where a EUROMIX 4000 with conveyor belts powered by reliable Watt Drive technology produces concrete for the motorway substructure.